- Textile Accessories

- Shuttle Loom Parts

- Textile Equipment

- 1511 Textile Machine Parts

- 1515 Textile Machine Parts

- GA615 Shuttle Loom Parts

- Textile Hardware And Tools

- Weaving Machinery

- Textile Auxiliary Equipment

- Textile Picker and Buffer

- Textile Wooden Parts

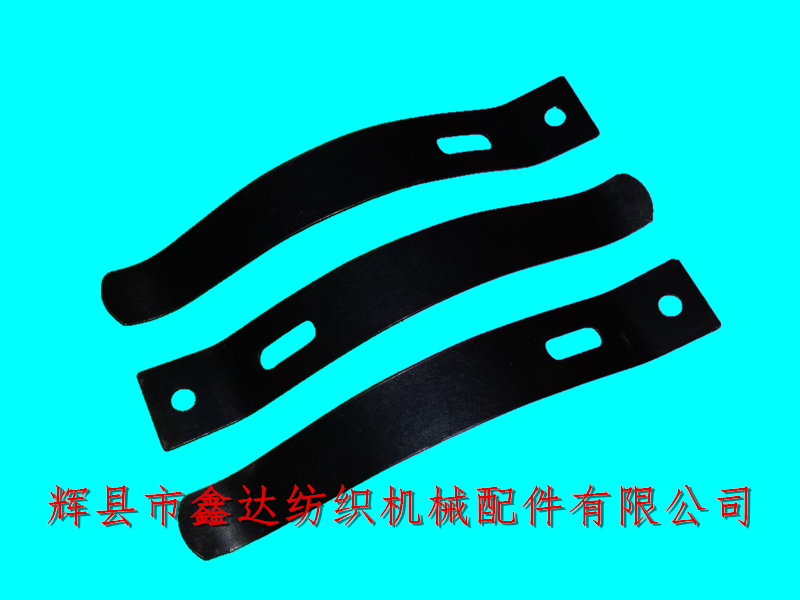

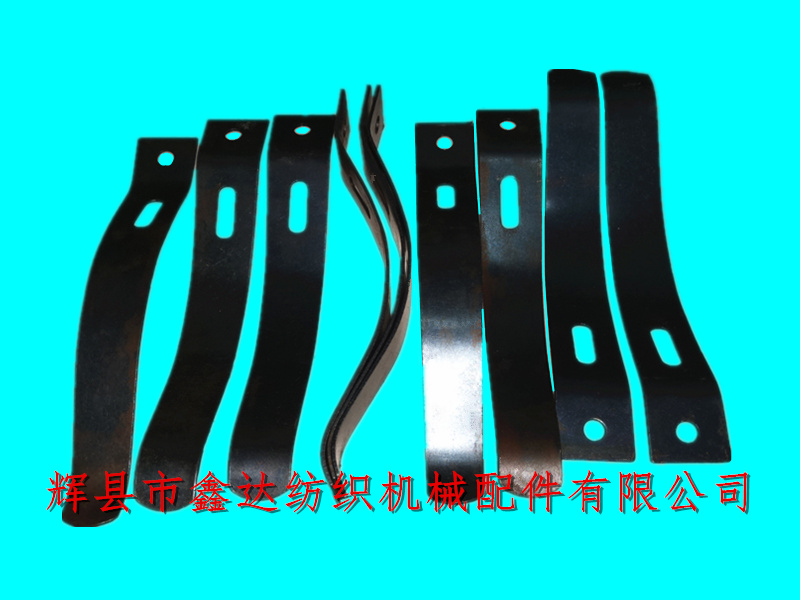

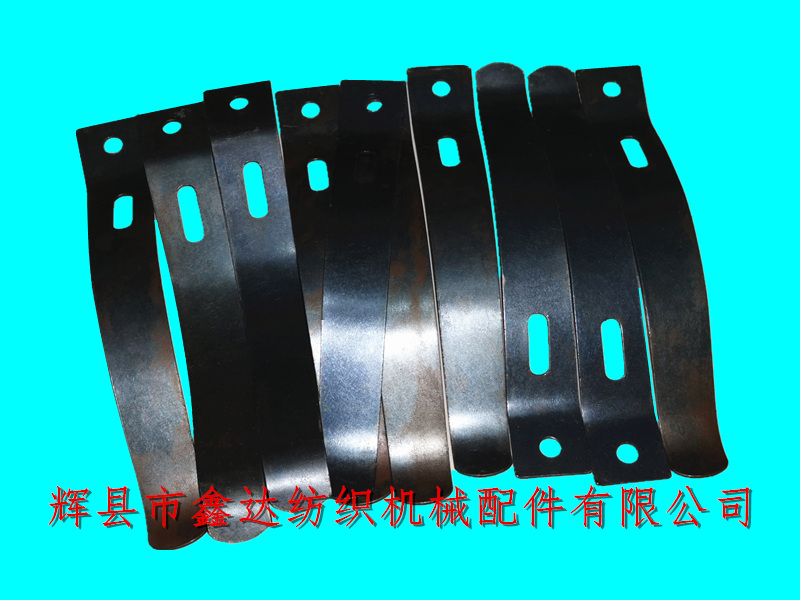

Huixian Xinda Textile Accessories Co., Ltd. has long provided 1515 multi shuttle accessories,Multi Loom Shuttle Box Back Plate Spring, The shuttle spring 8120 for the back plate of the multi shuttle box. The total length of the shuttle compression spring 8120 for the back plate of the multi shuttle box is 190mm, the thickness is 1.5mm, the diameter of the round hole at the tail is 8mm, the inner length of the side chute is 23.7mm, and the inner width is 8mm. The material is 60Si2Mn steel. The number of used for each 1x4 multi shuttle box is 4.

The elasticity of the shuttle box spring of the 1515 multi shuttle loom is moderate. The single side multi shuttle box lifting mechanism is installed on one side of the loom's reed, and the other side is a fixed single shuttle box. There are usually two kinds of single side two shuttle boxes and one side four shuttle boxes, represented by 1x2 and 1x4. The number of shuttles used in this form is the same as the total number of shuttle boxes on the changing side. The number of continuous weft insertion of each weft yarn must be even.

The determination of the lifting movement time of the multi shuttle box is the premise of ensuring the normal change of the shuttle box. It must consider the picking time so that the whole lifting movement can be completed before picking; The picking time at the lifting side of the multi shuttle box is generally 44.5 ° when the crank shaft rotates (calculated by 2 turns of the crank shaft and 1 turn of the picking disk). At this time, the distance between the chest beam and the reed is 23.4 cm.

In order to complete lifting and lowering before picking, the multi shuttle box should start moving when the crank shaft turns to 285 ° and end lifting and lowering when the crank shaft turns to 432 °, so that there is a short time for the shuttle box to be stable after lifting and lowering before picking.

The packing method of the Multi Loom Shuttle Box Back Plate Spring 8120 for the back plate of the 1515 multi shuttle box is: 20 pieces per bundle, 600 pieces per box, and the weight of a single shuttle spring is about 0.05kg. If you need to purchase textile springs, loom compression springs, textile leaf springs, multi shuttle springs, shuttle springs and 1515 accessories, please contact Mr. Yang of Xinda Textile accessories for consultation or negotiation!