- Textile Accessories

- Shuttle Loom Parts

- Textile Equipment

- 1511 Textile Machine Parts

- 1515 Textile Machine Parts

- GA615 Shuttle Loom Parts

- Textile Hardware And Tools

- Weaving Machinery

- Textile Auxiliary Equipment

- Textile Picker and Buffer

- Textile Wooden Parts

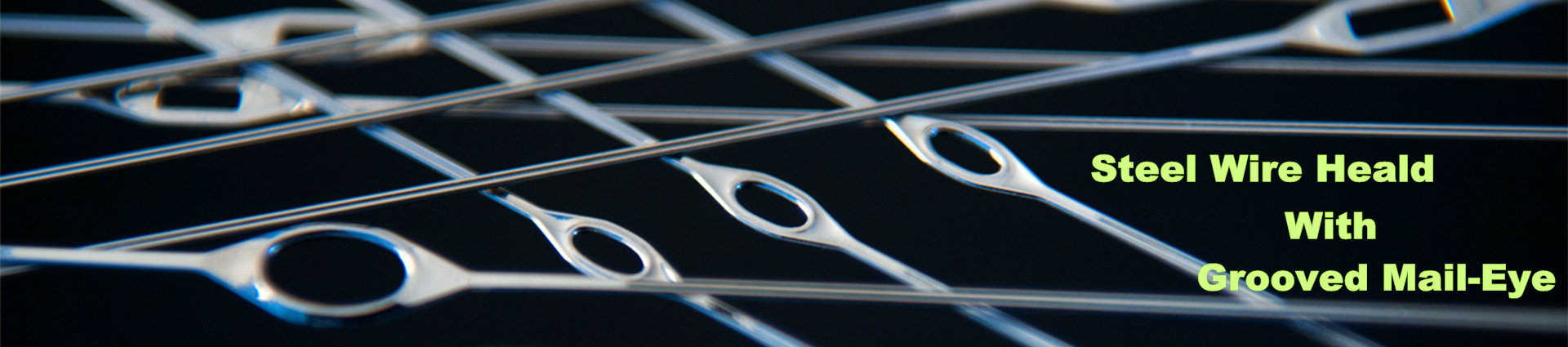

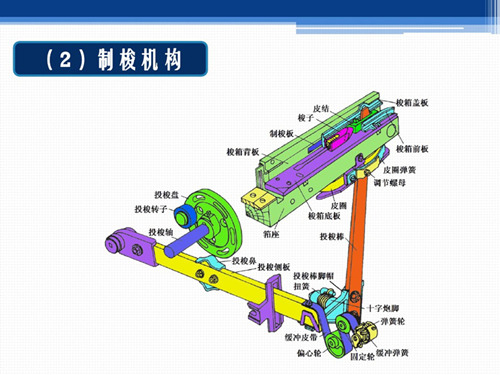

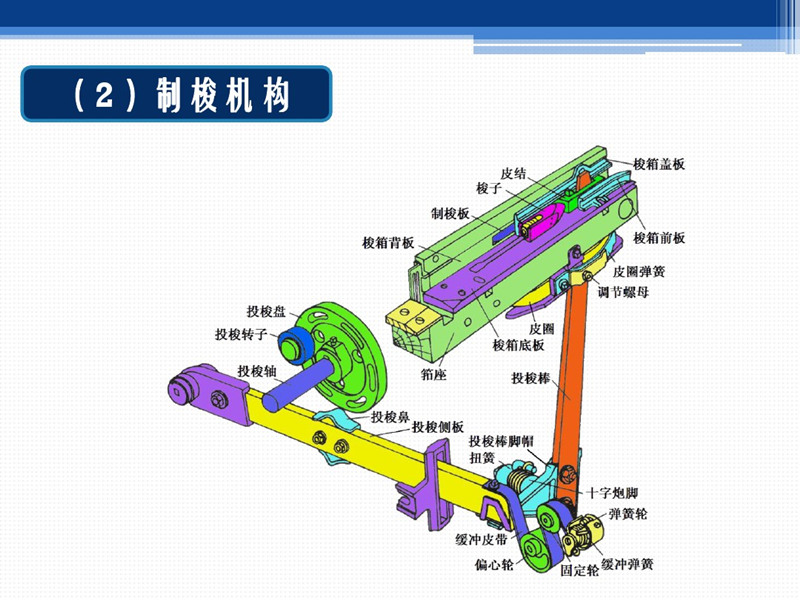

Principle Description Of Picking Mechanism of Chinese Loom (Figure)

As for the principle of picking mechanism of domestic Loom, the models of Loom used are different according to the different uses and fabric materials. According to the principle of picking mechanism, they can be divided into upper picking, middle picking, and lower picking. H212 wool looms use middle picking, and 1511, 1515, GA615 and other domestic Loom use lower picking. This article focuses on the structure and principle of lower picking of domestic looms.

It can be seen from the structure diagram of picking and making of the Loom shown in the above figure that the power of the machine comes from the picking shaft, that is, the pedal shaft. When the pedal shaft rotates, the picking rotor fixed on the picking disk F8 rotates along with the pedal shaft. When it hits the top of the picking nose, it generates downward force. The picking side plate moves downward in the guide frame F5, and the front end of the side plate presses the foot cap F14 of the picking stick downward, Rely on the Loom rocker (fixed F16 and F14) as the fulcrum, carry out lever movement, and the upper end of the shuttle board pulls the leather knot to hit the shuttle, making it fly.

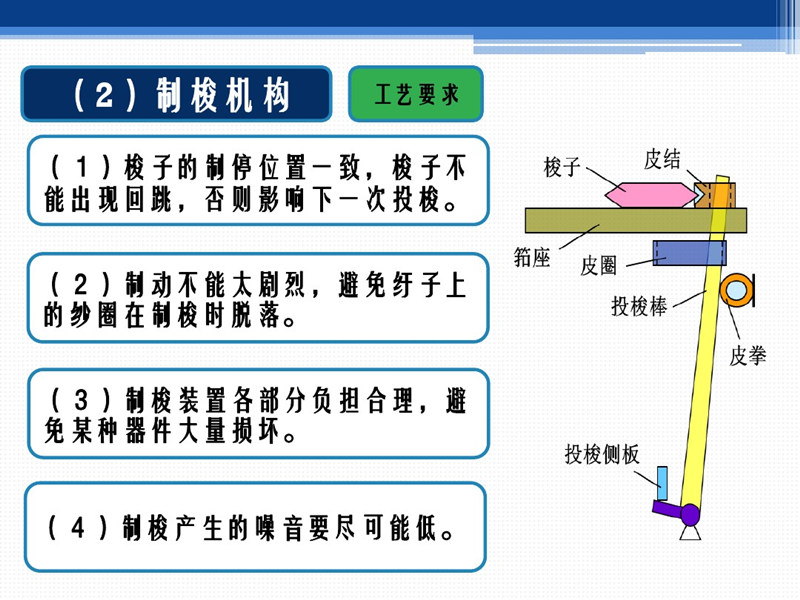

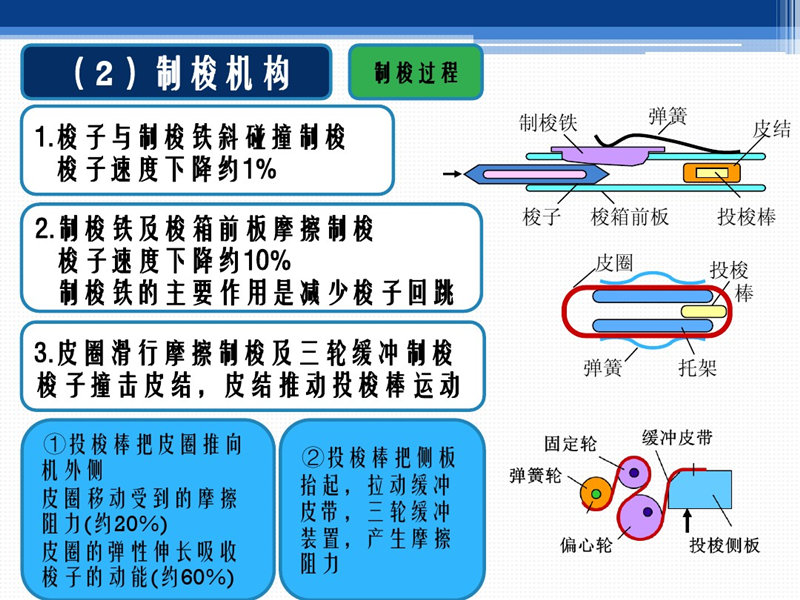

When the shuttle flies to the other side, it needs to slow down and brake. The structural principle of shuttle braking is to increase the friction between the shuttle box wall and the shuttle, and to add a buffer sliding box leather ring under the reed seat to stop it in a short time. The detailed braking requirements are as shown in the picture. If the shuttle braking effect is poor, the shuttle will rebound when it hits the leather knot and returns to its original position. This situation will cause significant damage to the leather knot. At this time, it is necessary to adjust the pressure on the shuttle iron in the back plate of the shuttle box and check the effective cushioning of the leather ring under the reed seat.

According to the lever principle, both sides of the domestic Loom are equipped with picking and shuttle making mechanisms, which are mutually complementary. This design has the characteristics of large adjustable range of picking force, long shuttle flight distance, etc., while the medium picking is generally suitable for weaving heavy looms with small door widths, or fabrics requiring large instantaneous picking force.

Loom, China Loom, Picking Mechanism,Mechanical Principles,Principles of Weaving.